Super precise mirror polish

focus

Precision lapping, flat lapping, precision polishing, precision grinding, any other precision manufacturing

Overview

TDC Corporation is a manufacturing company which mainly provide super precise polishing/lapping service.

Our expertise is...precision lapping, precision polishing, precision grinding, any other precision machining.

Our mirror polishing technology make the surface like a mirror, and achieve ultra flatness, parallelism, size tolerance, at the same time.

Characteristic technologies

Precision Polishing/Lapping technique is our core competence.

TDC's lapping technique can achieve not only smooth surface,

but also very precise flatness, parallelism, size tolerance, etc.

Roughness < Ra1nm

Flatness < 0.05um(100diameter)

Parallelism < 0.5um

Size tolerance +/- 0.3um

What we can achieve with lapping technique, other than flat surface.

Curved surface can be polished

Super precise ball (size tolerance +/- 0.2um)

Roll/Pipe polishing

micro cube

Foil (Stainless,Copper,Ti) can be polished with mirror surface.Thickness starts from 0.001mm.

・Material

Metals ( Stainless steel - SUS304 SUS316 SUS430 SUS440, Nickel, Copper, Aluminum, Titanium, Molybdenum, Tungsten, Tantalum……. STAVAX, etc),

Ceramics ( Al2O3, ZrO2, SiC, Si3N4, SiO2, etc.)

Resin ( Engineering plastics, Acrylic resin, PEEK, PMMA, etc.)

Glass ( BK7, Crystal, PYREX, Quartz, etc.)

Semiconductor material ( Si, SiC, etc.)

We continue to trying applying our technology on other new material.

・Field in Industry

Micro system industry , Nanotechnology industry , Automotive industry , Biotechnology , Chemical/Pharmaceutical industry , Printing industry , Electronics industry , Electrical engineering , Energy industry , Semiconductor industry , Aerospace industry , Mechanical engineering , Medical technology , Optical industry.....

Case Study in innovation

Mirror Fit Spacer - super precision shims / spacers / washers

TDC's super precision shims, spacers, washers enables you super precise assemble.

What is the advantage of TDC's Spacer??

・Thickness starts from 0.001mm.

・You can order from one piece to mass production.

・You can make its surface like a mirror (Mirror Fit Spacer)

note: standard shim/spacer doesn't have mirror surface

・You can order special size or shape.

Difference between Mirror Fit Spacer and Normal Spacer

Mirror Fit Spacer

Roughness:Ra1nm

You can see TDC logo reflecting on the spacers.

Normal spacer

Roughness:Ra70nm

You can't see TDC logo on the surface of spacers.

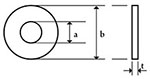

TDC Standard Shim / Spacer

TDC prepare standard type shim / spacers in stock.

| Material | SUS304 |

| Size tolerance | +/- 0.001 |

| Type | Size(a) mm | Size(b) mm |

| M2,M3 | 3.3 | 6.0 |

| M4 | 4.5 | 8.0 |

| M5 | 5.5 | 10.0 |

| M6 | 6.5 | 12.0 |

| M8 | 8.5 | 16.0 |

Thickness in stock(mm)

0.010 , 0.011, 0.012, 0.013, 0.014, 0.015, 0.016, 0.017, 0.018, 0.019, 0.020, 0.030, 0.040, 0.050 , 0.040 , 0.050, 0.060, 0.070, 0.080, 0.090, 0.100

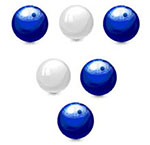

Super precision ball

TDC apply its polishing/lapping technology to manufacture super precision ball. We are challenging to develop further precision ball.

| Size | 0.5mm - 25mm |

| Size tolerance | +/- 0.0005mm |

| Sphericity | 50 nanometer |

| Material | any kinds. (e.g. metals, ceramics...) |

| Note | No scratch on surface ( mirror finished ) |

Super precision ball is used for - Probe - Stylus - Bearing -Master ball for precision measurement instruments other high precision application

Roll polishing,Pipe polishing(inside/outside)

TDC polish roll surface to Ra2 nanometer.

Our polishing technology makes it possible to make its surface roughness super fine, and keep its circularity.

| Size | up to 2500mm L |

| Material | Stainless steel,Titanium,Aluminum,Glass, Electro plating surface(Ni, Cr, Hard Cr) |

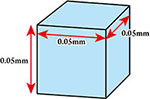

micro Cube manufacturing

TDC apply its lapping technique to manufacturing micro Cube.

| Size | 0.05 * 0.05 * 0.05 (mm) |

| Size tolerance | +/- 0.002 (mm) |

| Material | Any kind(Metals, Ceramics, Plastics, Semiconductor material, new material) |

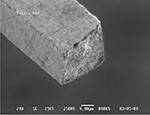

SEM Picture of 0.05*0.05 square bar

| Material | Cemented carbide |

Equipments

Company information

| COMPANY NAME | TDC corporation |

| SALE REPRESENTIVE | Natsuko Murakami (Ms) |

| natsuko@mirror-polish.com | |

| TEL | +81-22-356-3131 |

| FAX | +81-22-356-3578 |

| ADDRESS | 24-15 Chojamae,iidoi,Rifu-cho,Miyagi 981-0113,Japan |

| URL | http://mirror-polish.com/ |